cost savings, e-commerce, order fulfillment, orderfulfilment with e-commerce

Basic Inventory Management for Your eCommerce Fulfillment Center

So you’ve decided to outsource your eCommerce Fulfillment for your on-line store. Now you have to decide how much inventory to send to your fulfillment center, how much to order, when to re-order, and in general how to manage your stock levels and what the annual cost will be.

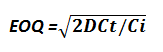

Simple Economic Order Quantity (EOQ) for your eCommerce Fulfillment Center

The first question you may ask yourself is: how much should I order from my supplier every time I place a replenishment order? Thankfully, there is a tried and true method for calculating this.

Where:

D = Estimated annual demand

Ct = transaction costs per order (receiving costs, order processing costs, transaction costs)

Ci = annual inventory cost per unit per year. (This includes obsolescence)

Example:

Let’s say you expect to sell 1000 widgets per year. Inventory costs are $5 per unit per year. And transaction costs are $12 per order receipt.

=69.28 = 69 units.

When should I reorder and what Should my Reorder Point be for my eCommerce Fulfillment Center?

Reorder level for your inventory is easily calculated.

Reorder Level = average lead time demand + safety stock.

Let’s say lead time is 4 weeks, and you want to have a minimum of 25 units in stock. Going back to the above example of selling 1000 units per year that equals (1000/52 X 4) = 77 units demand during the reorder lead time. So, your reorder level is 77+25 = 102 units.

You should order 69 units every time your inventory falls below 102 units.

** note there are ways to calculate what your optimal safety stock should be based on average demand and the standard deviation of demand and the service level you want to achieve i.e.: 99% of orders filled from stock. This is a little bit more complicated than the rest of the calculation in this article. You might want to just look at your demand and pick the largest weekly order you have and keep an extra week.

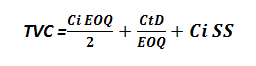

How much will carrying cost be for the Inventory I store at an eCommerce fulfillment center

Let’s use what we’ve already calculated from the above two examples. Your total annual variable cost of inventory can be calculated as follows:

Where ss = safety stock.

So, in the example we calculated 5*69/2 +12*1000/69 +5*25

=172.5 +173.9 + 125

= Your annual inventory costs for this item under this plan would be $471.40

Practical Implementation of These Calculations

Most on-line stores sell more than one item. Doing this calculation for hundreds or thousands of items can be very time consuming and impractical in the real world. The use of a spreadsheet where you can calculate one item per line and copy the calculation down the spreadsheet gives you an easy way to manage your inventory re-order points, order size and estimated annual cost of carrying your inventory.

Dare Marketing has solutions to help you manage your inventory and fulfill your ecommerce orders from our fulfillment center. We’ve got over 20 years of expertise and modern systems to help manage, pick, pack and ship your orders. Contact us! We’re here to help.

Leave a reply

You must be logged in to post a comment.